If you have decided to print your own labels in the office for your business needs, the next step is to get familiar with the process and the equipment you are going to need. The first thing to do is to buy a thermal printer and get to know the details of the thermal transfer printing as well as how thermal ribbons work. Don’t fret, as everything you need to know about the process is right here.

Thermal Transfer Printer

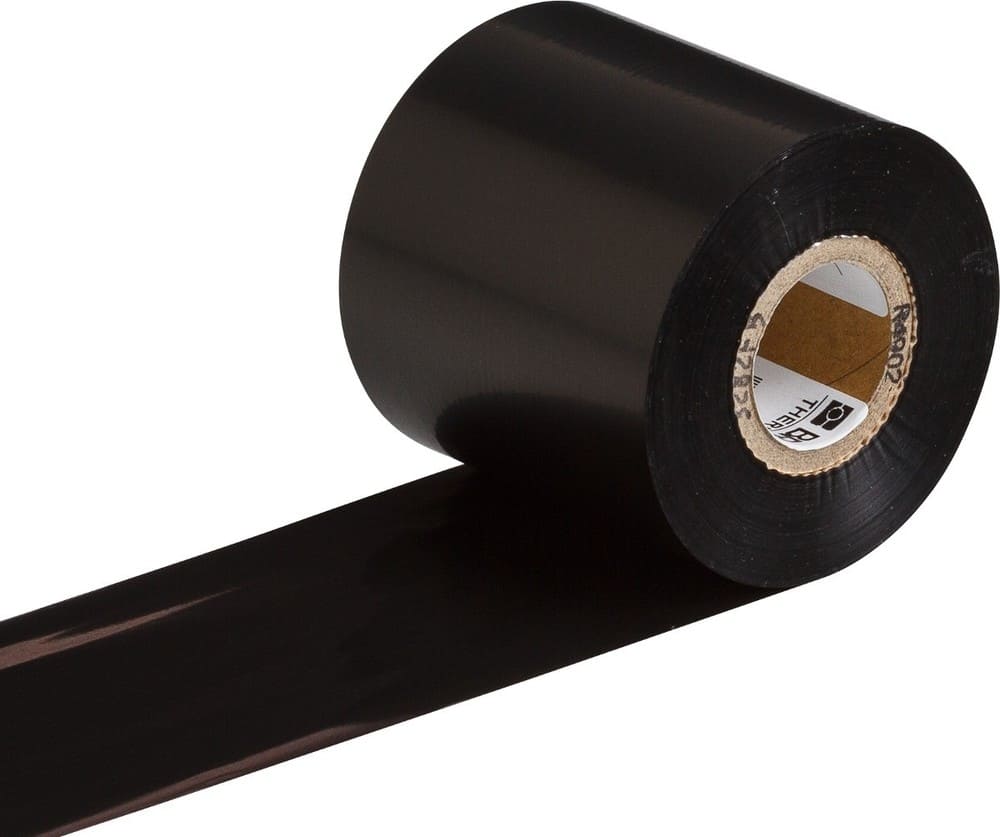

To start with, here is how the thermal transfer printer works. The printer prints on a substrate which can be a paper or another type of material by melting a coating of ribbon so that what is printed can stay glued to the paper. Because this process can work in several ways, there are three types of thermal ribbons: wax, wax-resin or resin and they come in a roll form. Usually, they are black but they also can be in another colour. There are ink formulas which are coated on one side of a thin polyester backing. Once the printer applies heat from the print head, the ink is released from the carrier and stuck to the label or the tag.

A Well-Matched Bond

The great thing about thermal transfer printing and thermal ribbons is that the process can be applied either on paper, on mid-range synthetics or even on glossy, hard paper. For each category, there are a great number of ink formulas selections. It is important that there is a well-matched bond

Things to Consider

When it comes to choosing the type of thermal ribbons, there are several things that you must consider. For example, the type of label stock you are going to print onto and the reason why and how you are going to use the labels. Do you want to use the labels for transport of goods

Wax Thermal Ribbons

Wax thermal ribbons are usually the ideal solution to print on coated and uncoated paper label stocks. They produce a high quality on high-speed applications. They are better to use for short-term labelling, however, they are still scratch resistant and can withstand the elements if used for outdoor purposes. The wax thermal ribbons are, in fact, for general use and to achieve high-quality print. A rule of the thumb is to keep the labels dry, not abraded or subjected to chemicals or oil because all of that would melt the wax image.

Wax Resin Thermal Ribbons

The

Resin Thermal Ribbons

Resin thermal ribbons are best to use on synthetic labels in harsh conditions including high temperature, chemicals, moisture and abrasion. The l