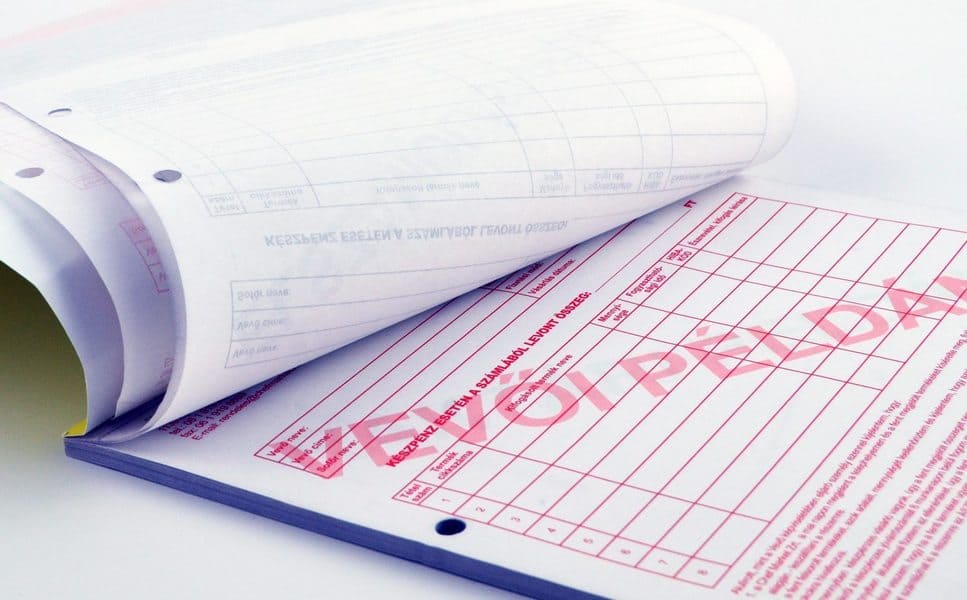

Carbonless Copy Paper is used in every business office where there is a need to make a multiple copies of a document. Since its appearance it has developed a lot – from carbon to carbonless and today its use is hugely widespread. Everything you need to know about it, you can read as follows.

The Lowdown on Carbonless Copy Paper

This eco-friendly and cost-effective paper is the perfect solution to use to convert continuous carbonless forms to a laser format. It was invented in 1954 and coated with two different types of chemicals which were kept in small capsules and released when the capsules were burst by pressure from a pen or a printer. This process produces a type of paper without the use of carbon, hence the name “carbonless copy paper”.

Types of Carbonless Copy Paper

There are two types of carbonless paper: traditional and laser. There is a difference between the two types. The traditional carbonless paper is produced with solvent-based chemicals that might damage essential printer components, including rollers, drums and other printer components. That is why, with the development of technology, a special type of carbonless copy paper was manufactured that was suitable to use in a laser printer. The imaging capsules are not solvent based so they don’t cause any damage to the components of the printer. Needless to say, the latter type is much more used in today’s printing.

Process of Printing

So, in order to create your own in-house forms, you need a pack of carbonless copy paper which can be printed in duplicate or triplicate copies. The carbonless copy paper can be used in a standard laser printer and a great advantage is that the paper doesn’t require the waxy carbon sheet in between the copies to create the image transfer. It actually works in a way that the image transfer is created from the chemical coatings on the paper which react with each other when they come in contact. Thus, it is very important to ensure correct loading into the printer so that you have

You need to know that each sheet prints one at a time, the same like the standard copy printer works. Taking this into consideration, you need to adjust the printing quantity to properly make use of it. If you want to make duplicate copies, you need to print two sheets and if you want to make triplicate copies, you need to print three sheets. Do the math correctly before pressing the button to avoid unnecessary mistakes.

The Finished Product

After printing, you can staple, paper clip or file the copies in a ring binder. Don’t forget to put cardboard underneath each set if you use the filing method so that you can make sure that when you write on the images it transfers only to the set you want to use. Another tip you can use is to apply pressure on the top of the copy sheet with a ball-point pen for a signature or a written text so that more departments or administrators can keep a record of the signed copy.